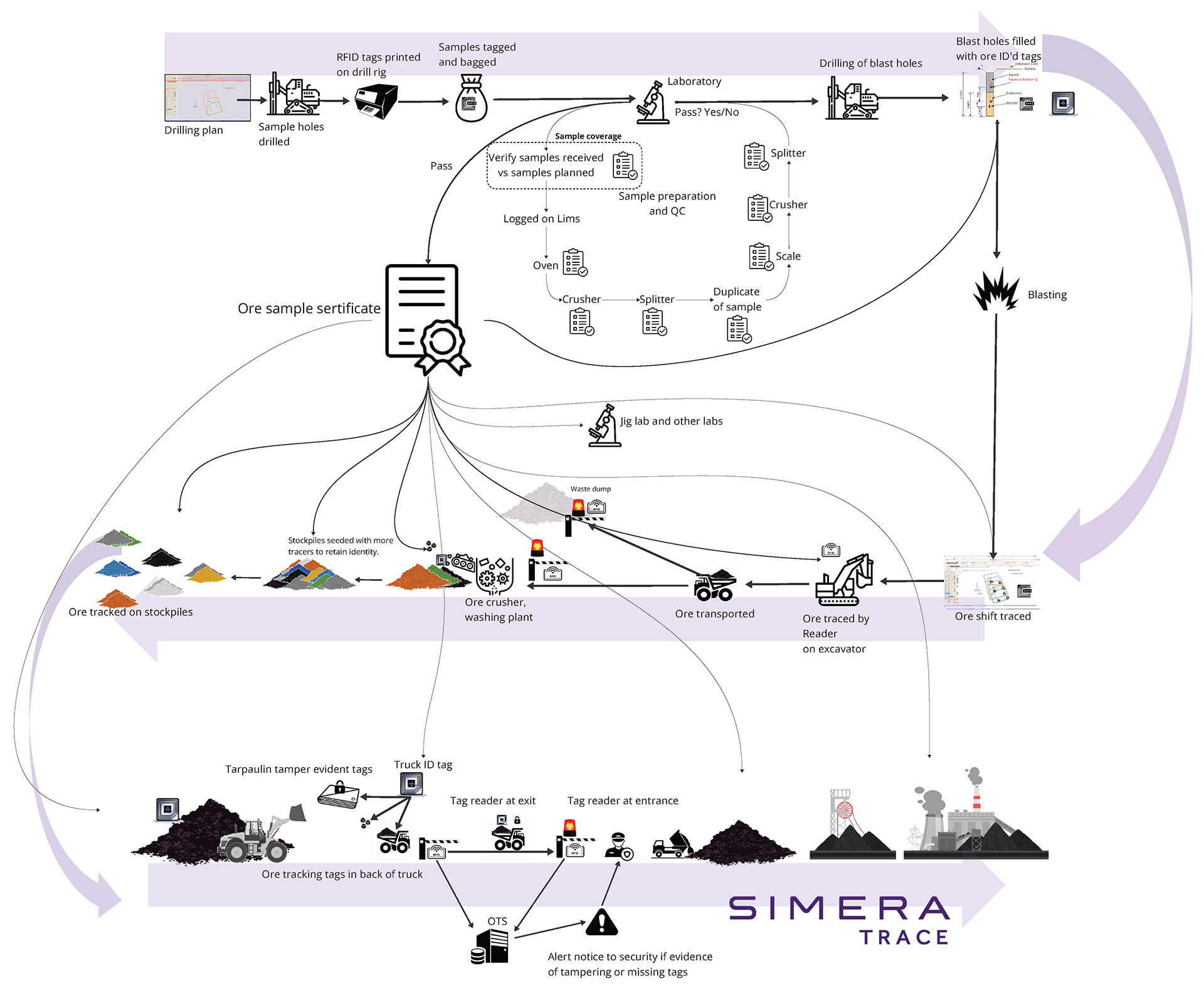

Measure while drilling

Raw drilling machine measurements are taken, analysed and reported in real-time. This enables real-time reporting on rock hardness and penetration rates. This enables timely blast designs for optimal results.

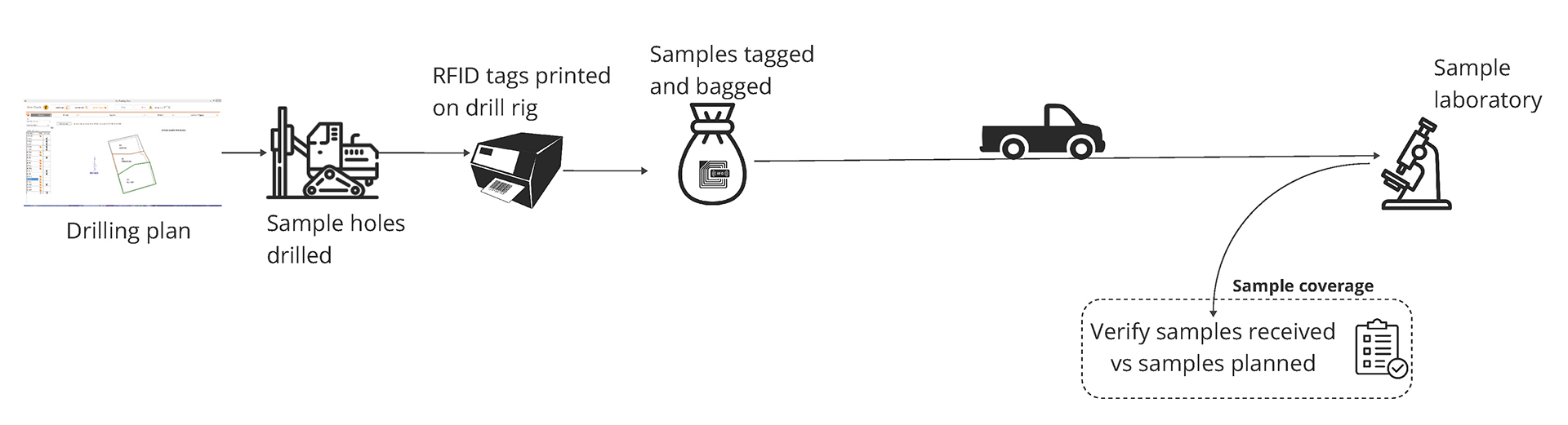

Sample Tracking

Digitally track samples from the pit to the lab. At the lab the samples are automatically read, registered and compared against the planned samples to be collected. This provides immediate confirmation whether there is compliance between the drilling plan and actual samples received. Increase sample recovery rates to 100%.

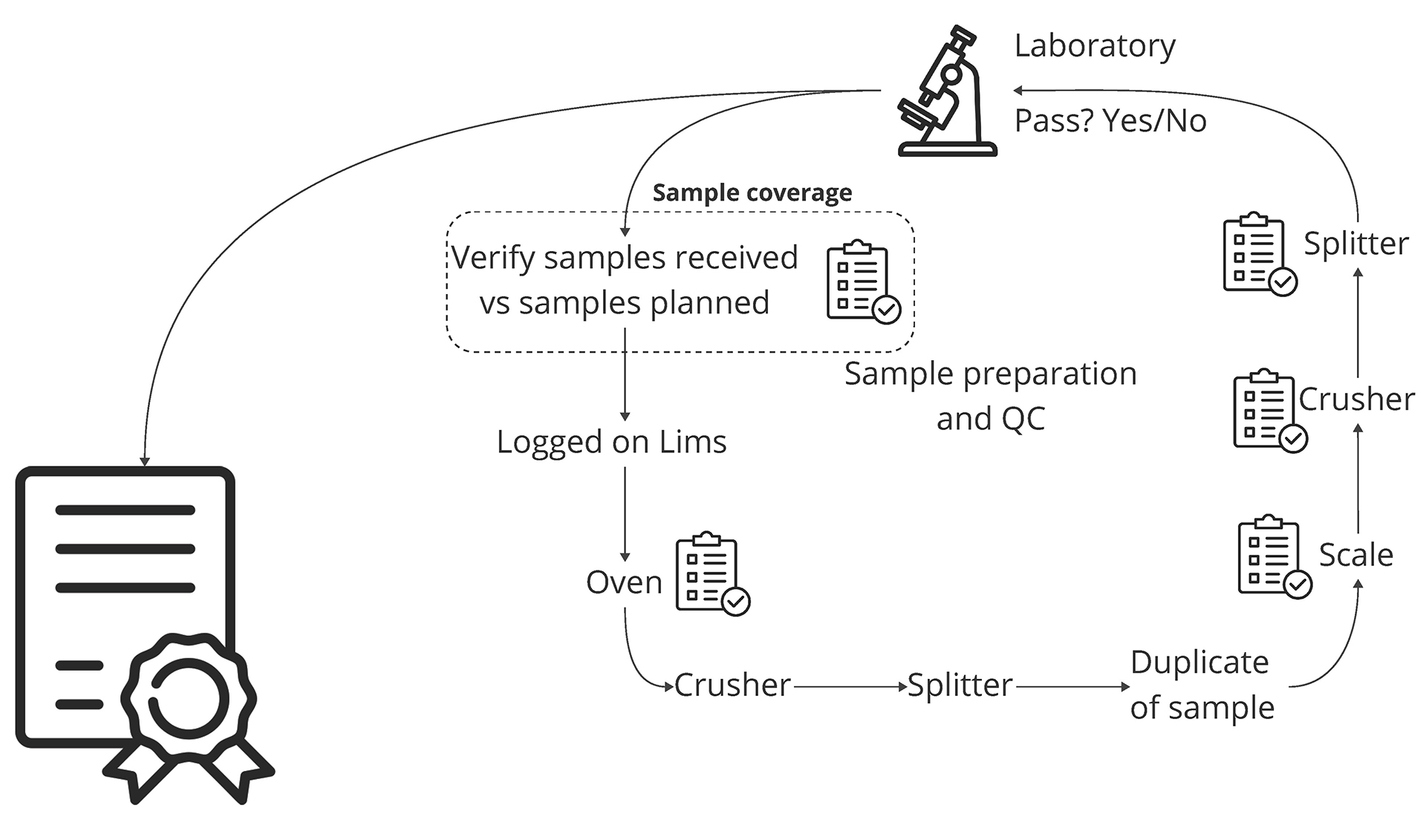

Sample laboratory protocol compliance monitoring

The intregrity of the sample analysis certificate depends on whether the lab protocol is followed correctly. The Sample Tracking Management System (STMS) not only tracks the movement of the samples through the lab, but also monitors who handles the samples, and whether the protocols are followed correctly. Only upon compliance with the protocol, is the sample certificate automatically issued. This certificate then becomes the identity of the specific batch of ore represented by the samples. STMS provides a verified digital identity for each batch of ore that can be traced at any stage of processing, stockpiling or transfer to End User.

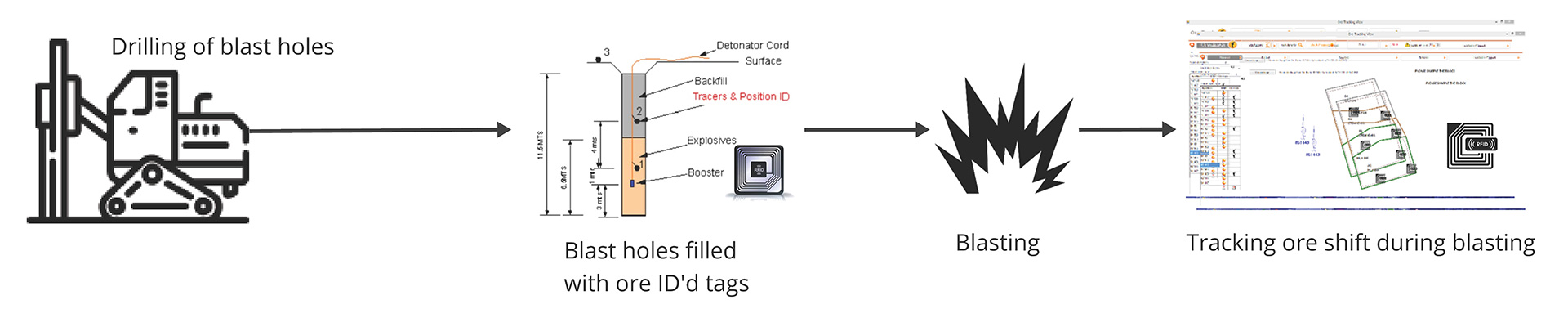

This certificate information is then linked with the physical SimTracers added to the ore in the blast hole. These SimTracers will accompany the ore throughout its entire life cycle, enabling the identification and digital tracking of the ore.

Grade control management system (GSMS)

GCMS is an unique application which tracks material before and after the blasting of a block on a mine. Tests have indicated that ore often shift up to 15 meters during blasting. Few mines take this into account, which often lead to the general term, “blind mining”. Grade control is used within the mining process to provide quality checks and control the grade and variability of ore.

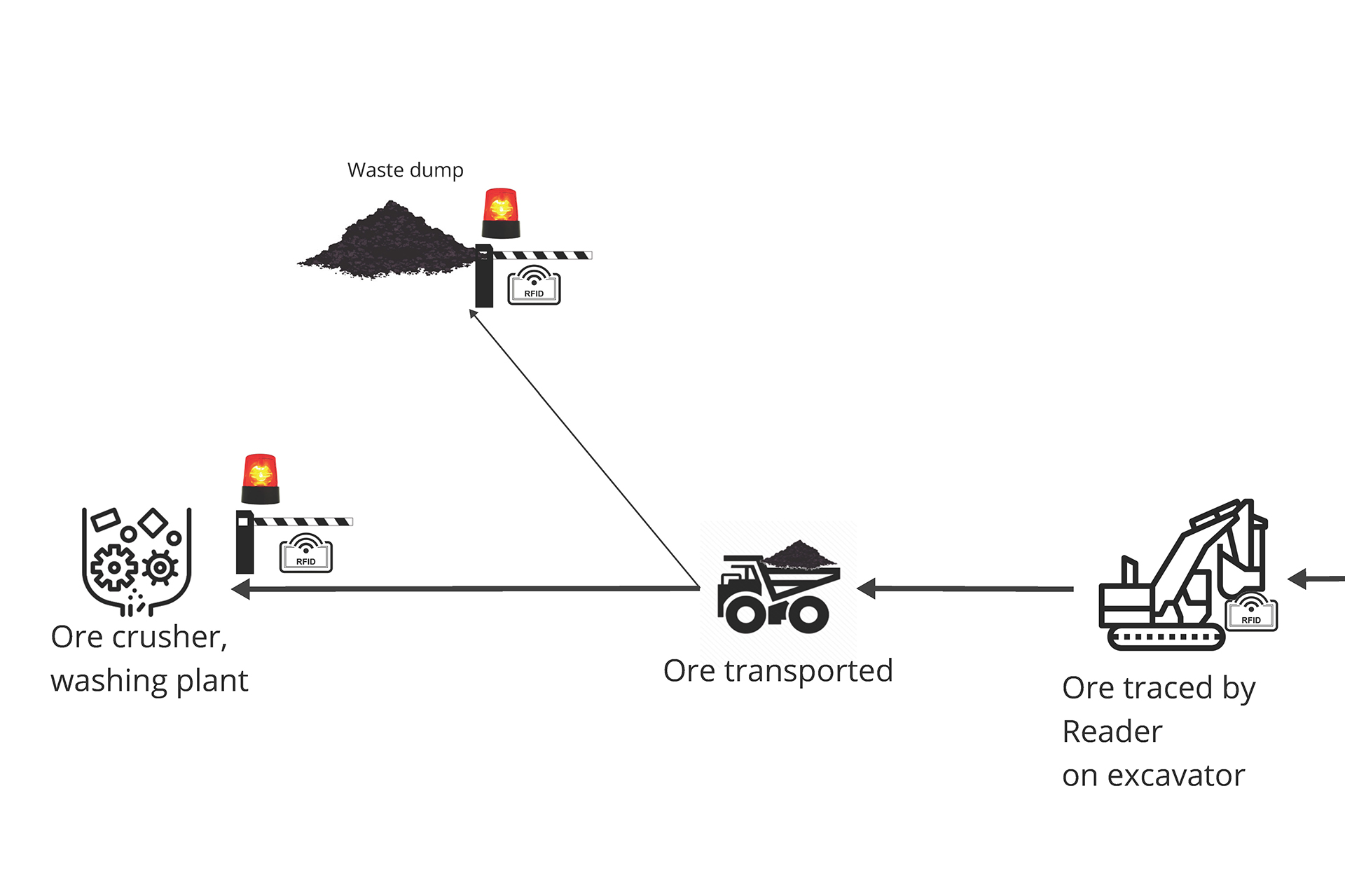

Preventing Ore-to-Waste and Waste-to-Plant

When ore is Tag and Traced, there is clarity about what is loaded with every excavator load. This means you can prevent dump trucks from deliberately or mistakenly deliver good ore to the waste dump, or waste to the processing plant.

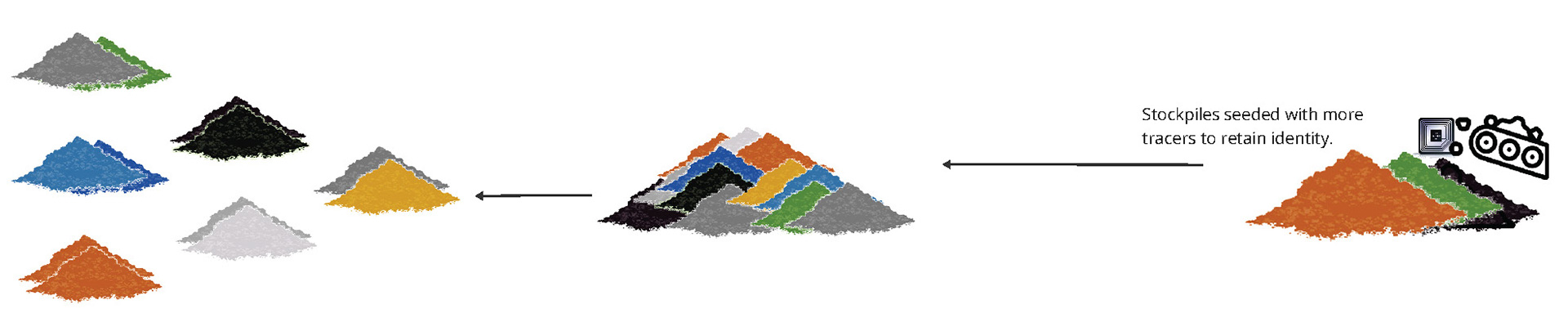

Stockpile mapping, ore blending and processing optimization

When the ore exits the production plant, its identity is read, and more tracers with the same identity can be added to ensure the ore body is well tagged throughout its life span. This means when ore is stockpiled, the stockpile can be mapped very accurately since the identity, quality and location of every batch in the stockpile is known. This enables accurate blending of ore to specific requirements.

Knowing what grade of ore enters the production facility, also enables the optimization of the processing plant.

Should the grade of a batch of ore change due to blending, the new identity from online analysers can be linked to the specific batch of ore.

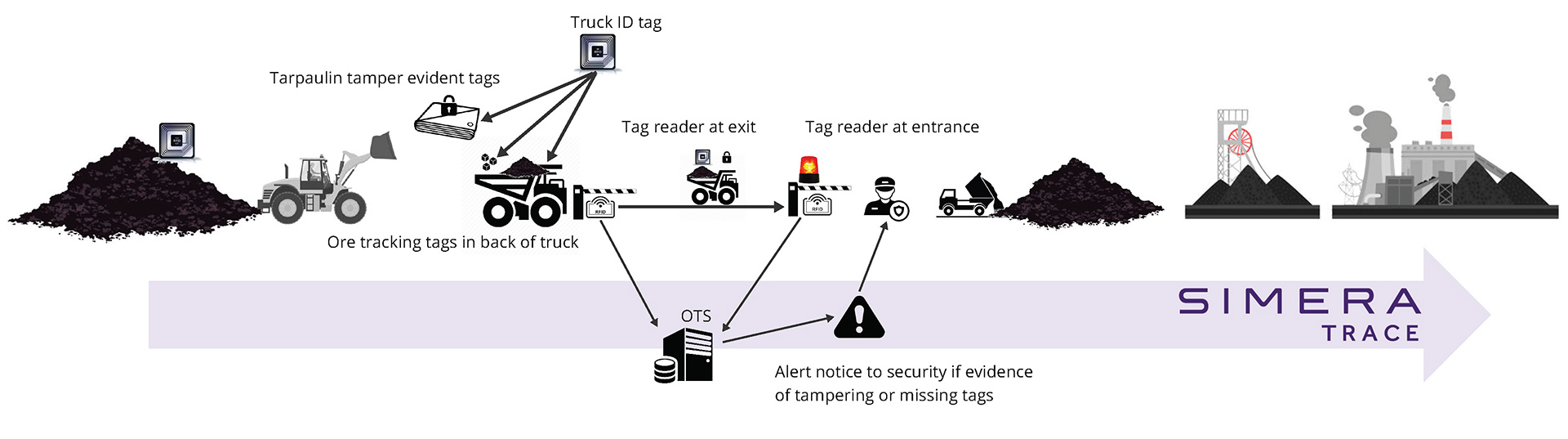

Ore security during transport

Every truck of ore can be seeded with unique tracers at its point of departure. Upon arrival at its destination, the system automatically detects whether there was any tampering with the ore. Only dedicated readers can communicate with the tracers, since they are password protected. This makes it very difficult for perpetrators to detect and remove the tracers. The system empowers you to know whether your ore was tampered with during transport. The digital audit trail provides secure evidence when prosecuting perpetrators.

Ore sample certificate linked to ore body throughout the entire value chain

Once the ore samples are certified, that certificate becomes the digital identity of the ore body. This identity accompanies the ore body from the point of blasting, throughout its value chain to final delivery or consumption. The digital identity provides an audited trail for the ore body that enables ore data integration into digital system optimisation tools that enables Mining 4.0.

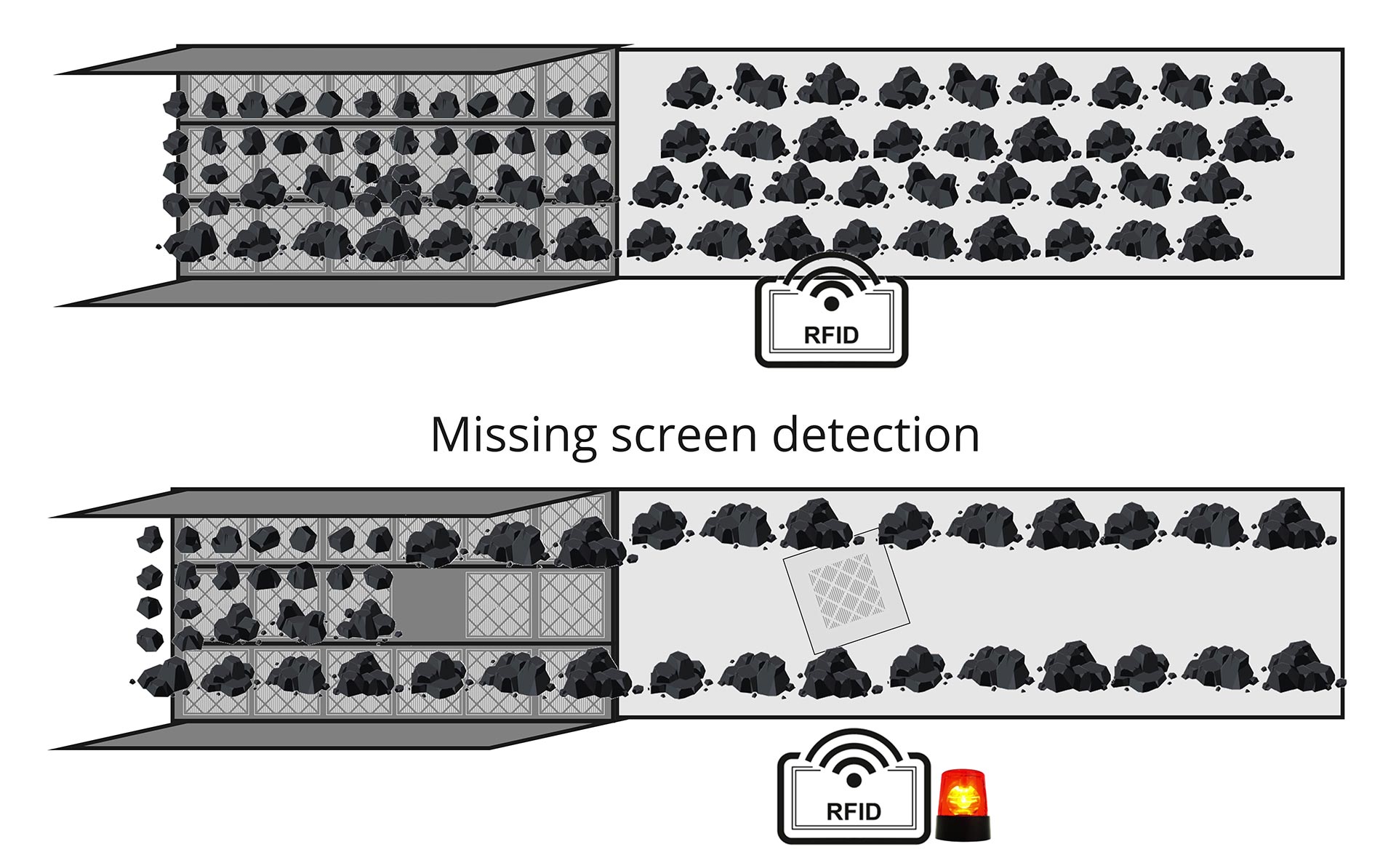

Missing screen detection

Our system detects dislodged screens within seconds. The moment a dislocated panel is detected, the feed conveyor to the screen is stopped. This limits the contamination of the ore in the discharge and avoids large penalties.

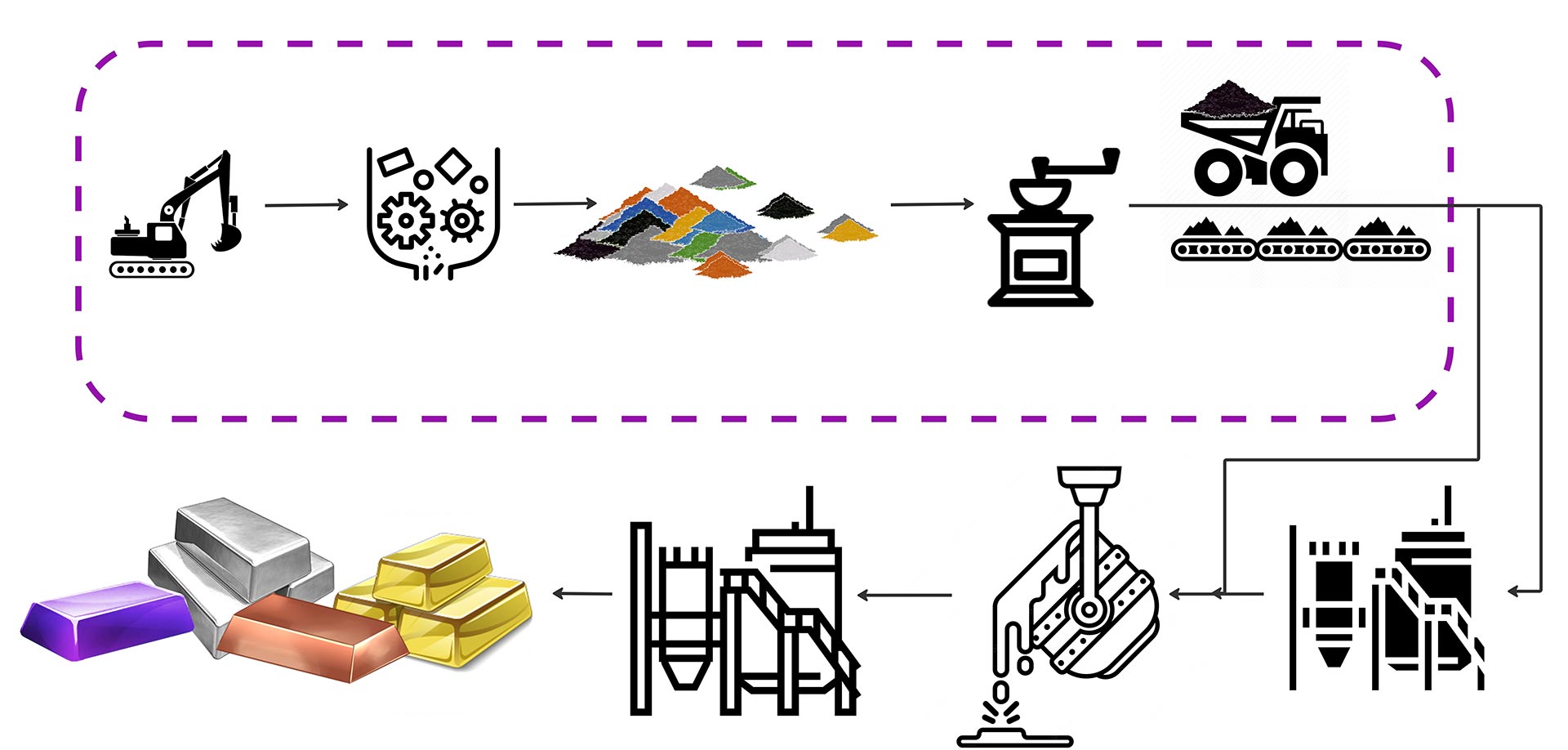

Metal Accounting

Digital ore tracking during the mining, crushing, stockpiling, grinding and transport phase assist in making metal accounting much more transparent and real-time reliable compared to existing techniques.

Asset tracking with accountability

The system also enables equipment tracking to-and-from repair agents, major spares from stores to workplace to repair agents, and monitoring of strategic assets like LP gas bottle and fire extinguishers.

The result is an improved asset audit trail, automatic surveillance and improved inventory control and turnaround time management.

Missing person location

Proposed changes to the Mine Health and Safety Act include the introduction of a mandatory missing person locating system. This means that all underground mines and surface mines with a significant risk of slope failure must provide their workers with a device that enables the mine to locate workers if they go missing while working or during an emergency.

Workers can be traced to their last position after slope failure. This enables rescue teams to know exactly how many miners are trapped and where to search for them. With a suitable tracing infrastructure underground, management will be able to manage their staff logistics in real-time, detect activity in prohibited areas, and do rapid PPE compliance verification at any point in the mine.

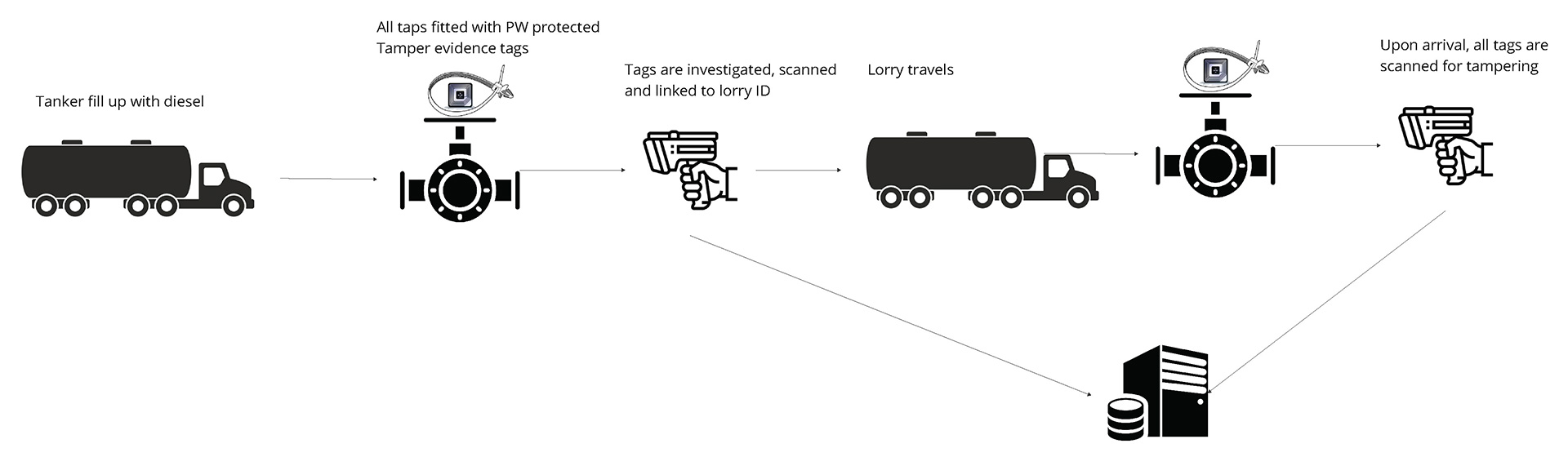

Liquid petroleum security during transport

When transporting high value liquids, perpetrators often exchange some segments in the tanker with water. Tampering can be detected with password protected tamper evidence tags which are scanned with hand-held scanners before departure and before delivery.