The future of mining

The future of mining will be shaped by automation, robotics, AI and data analytics. Core to this is the unique and defined economic signature of the ore deposit. Knowledge of the ore body and the ability to detect, identify and trace it, will enable the optimization of ore grade control and the processing plant. This will be the difference between success and failure for many mines.

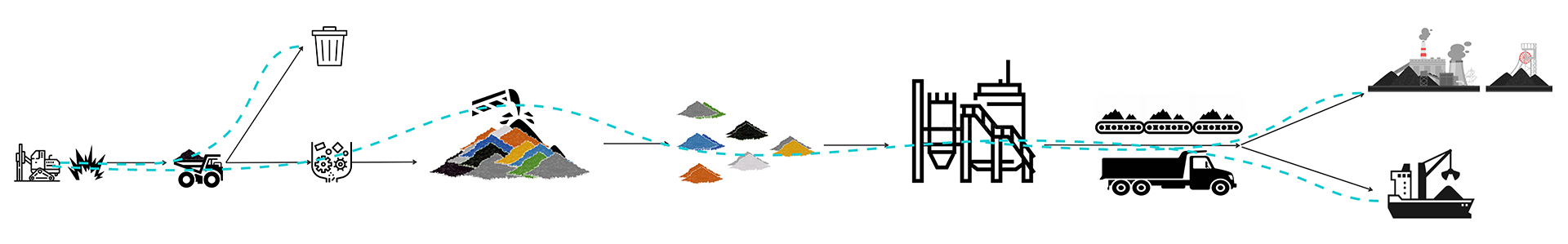

Ore tracking with digital ore trail

The ability to track ore digitally creates tremendous advantages. It prevents ore from being dumped as waste, and waste being crushed and processed. Identified and tracked ore also enable accurate management of stockpile grades and retention time. Prior to processing, digitally tracked ore can be blended for optimal results. Finally, it enables the validation of ore identity during and after haulage to point of consumption or sale. Creating a digital ore trail enables the digital simulation and optimization of processing plants and auditable trail of events from which intelligence can be derived..